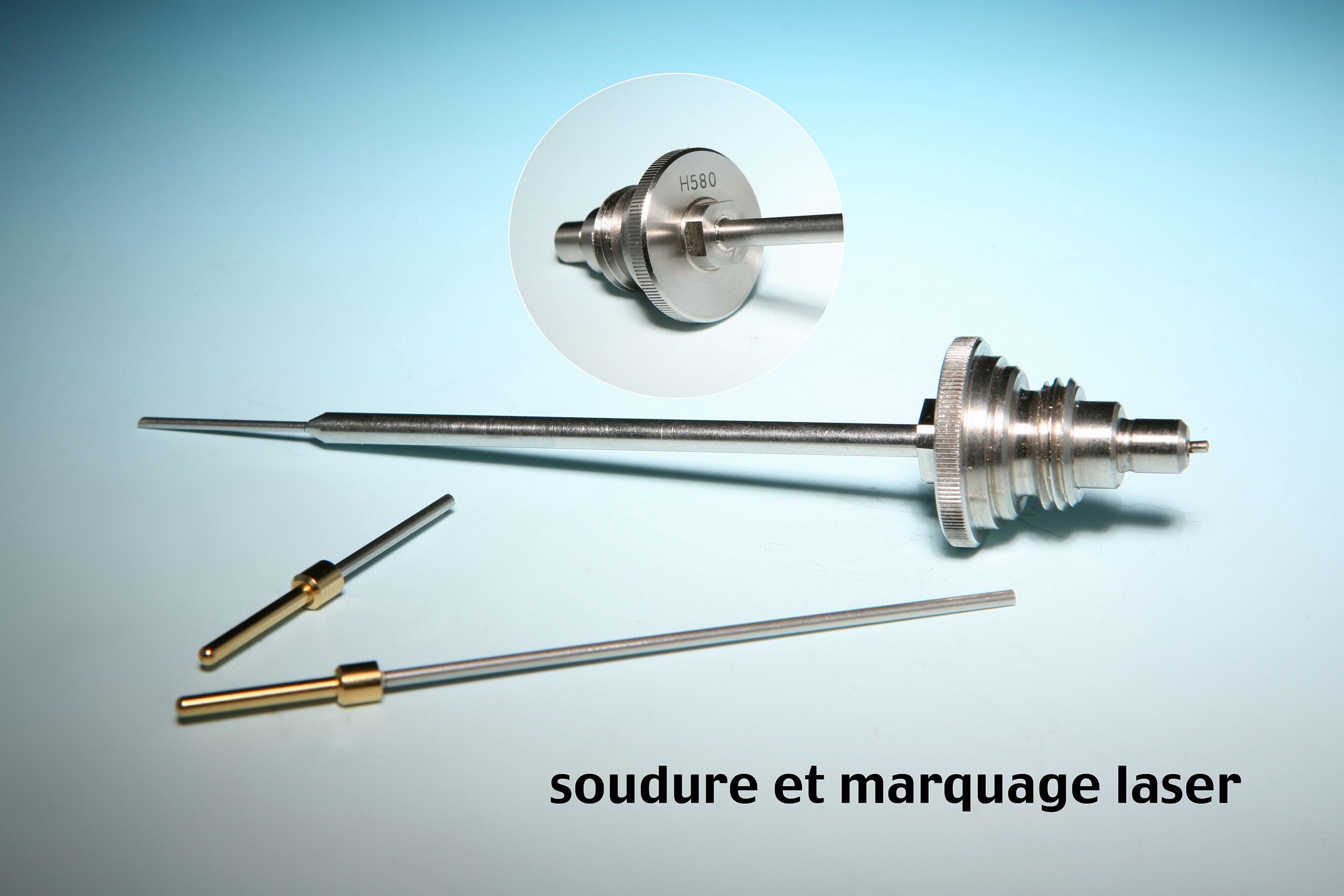

Laser welding for machined parts

Laser welding is a technique that allows several pieces of metal to be joined using a laser.

The beam is an extremely concentrated heat source which allows precise and resistant welds while maintaining a fast rate.

In the medical industry for implants in particular; it is the aesthetic aspect of laser welding and the absence of filler metal that encourage the use of this technology because there is no change in the biocompatibility of the initial material.

ARCOM Industrie has many tool configurations that allow us to process the most demanding welding geometries, including tubular microweld.

Our strenghts

- High mechanical resistance

- Homogeneity of the weld

- Localized microwelding

- No filler metal = guaranteed biocompatibility

- Quality guaranteed by 100% control

- Leaktightness of welds guaranteed by leak detection test

- Repeatability of the process

- Economical: quick implementation and great flexibility

- Small to large series

Application domain

- Medical

- Vacuum and UHV

- Electronic

- Optical

The advantages of laser welding and microwelding

- Biocompatible: No risk of contamination of welded metals, without filler metal

- Great mechanical resistance

- Aesthetics: very fine and clean welding

- No deformation

- Laser precision: localized welding

- Welding dissimilar materials

- Waterproof welding, guaranteed 100% by waterproof test

- Fast implementation and great flexibility

- Possibility of welding circular or flat parts

- Possibility of tubular welding