Complex machining

Complex Machining: Arcom, your partner to meet new challenge.

ARCOM Industrie does machining and parts manufacturing according to the requirements of its customers, including complex machining and 5-axes machining.

Our industrial expertise allows us to meet the expectations of demanding sectors such as medical, aeronautics and space but also vacuum and ultra-high vacuum.

The mastery of new machining technologies allows Arcom Industrie to provide solutions for the production of difficult parts, while bringing significant productivity gains.

Complex Machining: For which types of parts?

We are machining all types of complex shapes: cams, ramps, propellers.

Our polyvalent machine park allows us realization in a wide range of dimensions:

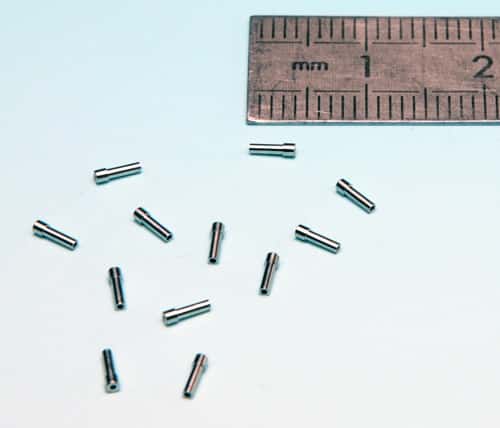

Very small diameters from Ø 0.50 to larger pieces up to Ø300.

Complex machining and machining 5-axes: For which materials?

Our experience of demanding market gives us a perfect mastery of the machining of “exotic” materials:

- Titanium

- Inconel

- Monel

- Tungsten

- Nickel

- Hastelloys

A last generation park machine:

Installed on a site of 3000 M², our powerful and flexible production tool enables us to offer complete services and to answer the needs of the most varied markets.

We have a modern machine park composed of:

- Multifunctional towers:

- Mobile doll towers,

- Bi-spindle / bi-turret lathes

- And 5-axis machining center and UGV

Automating our processes, reducing assembly time and acquiring multitask equipment help increase productivity and flexibility.

Complex machining and innovation:

Equipped with CAD / CAM SolidWorks + SolidCAM, our design office works in co-design with our customers and partners to improve and optimize their products.

For several years, ARCOM Industrie collaborates with various research centers and school environments in order to participate in the increase of its competitiveness the improvement of its knowledge.

Complex machining and Quality: A measurement chain at the cutting edge of technology:

ISO 9001 certified by AFAQ, our quality department is equipped with high-performance human and material resources to ensure an irreproachable level of quality.

We have equipped ourselves with powerful means of control to ensure the follow-up of our fabrications:

- Three-dimensional measuring machine

- Non-contact measuring machines

- Profile measuring devices

- Shape control device: concentricity, cylindricity

- Roughometer